PROJECT'S CONTEXT

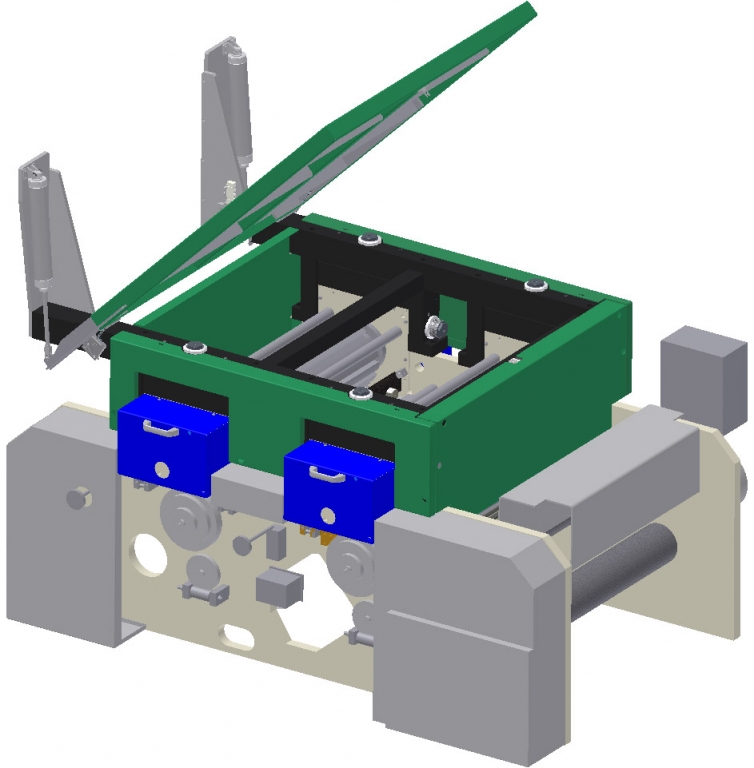

Our client, a global leader in the lottery industry, wanted to modernize a production equipment and improve its support mechanism to ensure the repeatability of the cassette positioning during the perforation of the product.

BENEFITS CITED BY THE CLIENT

- Expertize in web products manufacturing

- The versatility of services

- Their expertise abroad

- A detailed evaluation of the manufacturing costs

EGZATEK'S CONTRIBUTION:

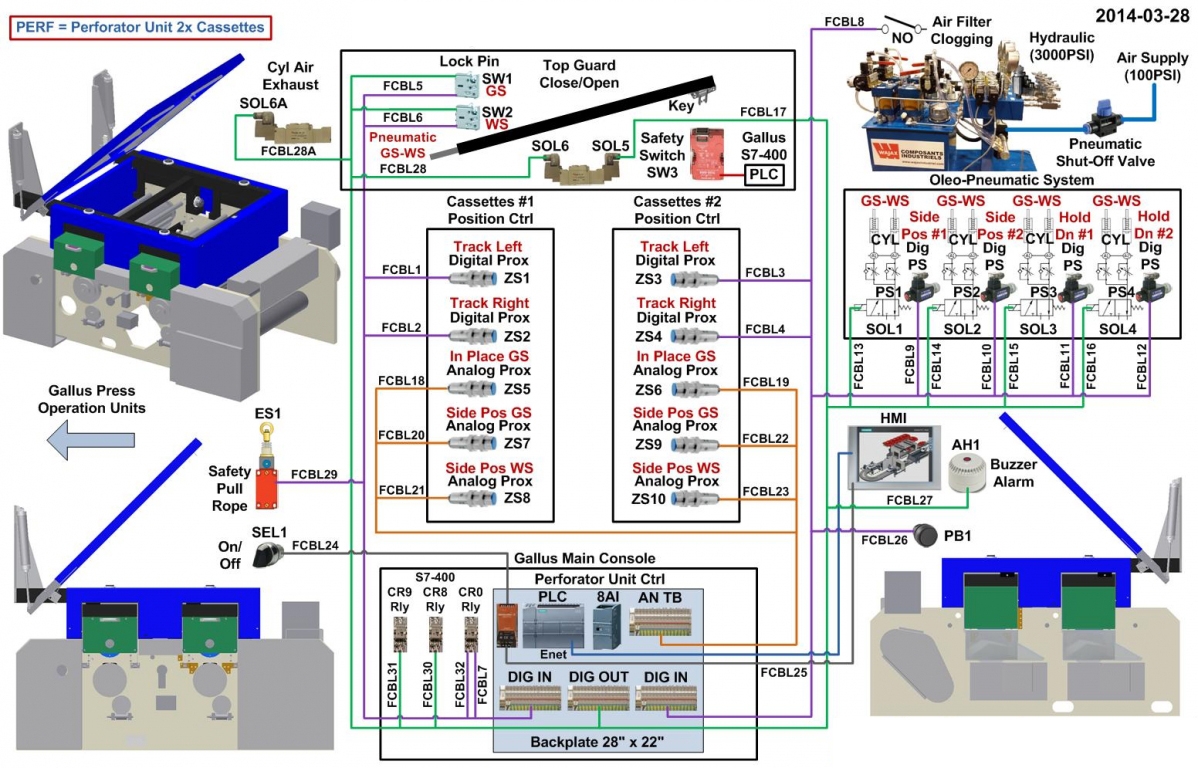

The engineering team's creativity has led to the development of a process that holds down the cassettes with hydraulic pressure. The new system makes it possible to apply a greater load during the perforation process by simply increasing the hydraulic system's pressure. With this new equipment, which has a control panel, the PLC and the HMI will enable the validation of the cassettes positioning in the machine and the activation of the support mechanism if necessary.